What is the production process of welding rotator?

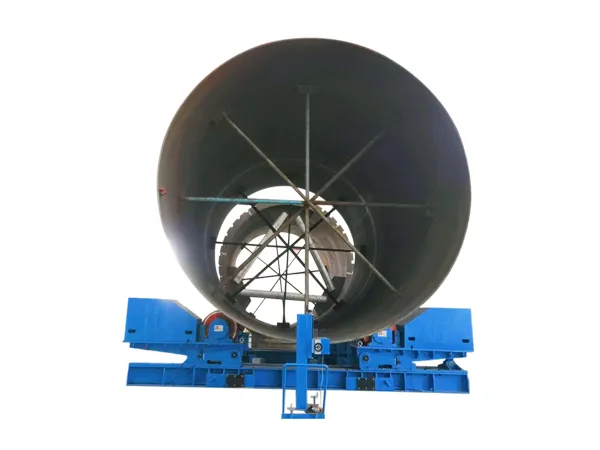

Welding rotators are essential equipment used in various industries for rotating cylindrical workpieces during welding or fabrication processes. The production process for welding rotators typically involves several key steps.

Welding rotator production process

Design and Engineering

Begin with designing the welding rotator based on customer requirements, taking into account the size and weight of the workpieces to be rotated.

Consider factors such as load capacity, rotation speed, and the diameter range of workpieces.

Material Selection

Choose materials with high strength and durability for the main frame and rotating components. Common materials include steel alloys.

Cutting and Shaping

Use cutting machines, such as plasma or laser cutters, to shape the main components of the rotator, including the base, frame, and rotating rolls.

Welding

Assemble the cut components and weld them together using various welding techniques, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding.

Ensure proper alignment and structural integrity during the welding process.

…

For more detailed information about the production process of welding rotator, please click here: https://www.bota-weld.com/en/a/news/welding-rotator-production-process.html