Vibrating Screen Exciter Guide: Design, Key Components, and Performance Optimization Tips

The vibrating screen exciter is the core of any screening system. It generates the vibration force needed to move materials across the screen surface, directly affecting efficiency, throughput, and machine lifespan. A high-quality exciter ensures stable performance, reduced maintenance costs, and improved product quality.

This guide covers key components, structural design considerations, and optimization strategies to help engineers, plant managers, and buyers make informed decisions.

What Is a Vibrating Screen Exciter?

A vibrating screen exciter (also called an exciter unit) is a mechanical device that converts rotational energy into oscillations required for effective material screening. It is widely used in:

Mining and mineral processing

Aggregates and construction materials

Coal preparation

Metallurgy

Chemical and recycling industries

A well-designed exciter ensures stable vibration amplitude, balanced force output, and consistent screening efficiency.

Key Components of a Vibrating Screen Exciter

Understanding core components is essential for selection, operation, and maintenance:

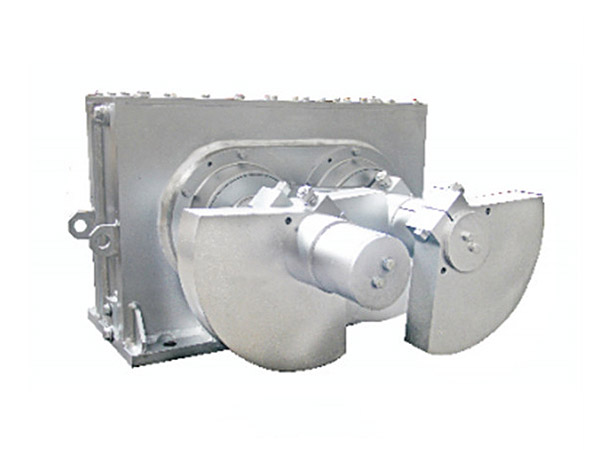

1. Housing / Exciter Body

Supports bearings, shafts, and gears

Made from high-strength steel or cast alloy

Precision machining ensures stable vibration

2. Shaft(s)

Single or dual shaft depending on design

Transmits rotational force

Heat-treated to withstand heavy cyclic loads

3. Bearings

Heavy-duty spherical or cylindrical roller bearings

Designed for high-speed rotation and vibration stress

Bearing quality directly impacts exciter lifespan

4. Gears

Synchronize shaft motion

Ensure accurate vibration amplitude and direction

5. Lubrication System

Oil or grease-based depending on design

Prevents premature wear and overheating

Critical for long-term reliability

Structural Design Factors Affecting Exciter Performance

Several structural elements influence exciter performance. Optimizing these ensures higher efficiency, lower downtime, and longer equipment life.

…

For more detailed information on the structural design of vibration screen exciter guidelines, please click to visit: https://www.hsd-industry.com/news/vibrating-screen-exciter-structure-design/