Comprehensive Analysis of Slewing Bearings: Classification, Selection, and Application Guide

In modern industrial equipment, slewing bearings are core components for achieving rotary motion, widely used in cranes, wind turbines, steel structure rotary tables, and tunnel boring machines. They can withstand not only large radial loads but also axial forces and overturning moments, directly affecting the safety and efficiency of the equipment. This article will systematically analyze the classification and selection points of slewing bearings to assist in engineering practice.

Main Classifications of Slewing Bearings

Slewing bearings can be classified according to the type of rolling elements, structural form, and installation method. Different types of bearings are suitable for different engineering needs and load conditions.

1. Classification by Rolling Element Type

Spherical Slewing Bearings: Use steel balls as rolling elements, resulting in low frictional resistance and flexible operation, suitable for light to medium load scenarios.

Typical Applications: Industrial robots, light lifting machinery, etc.

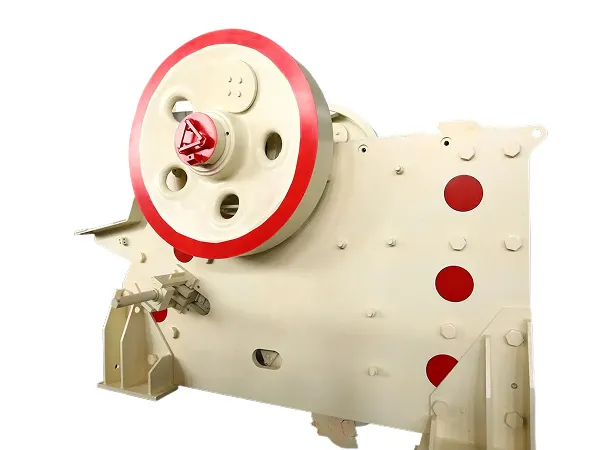

Roller Slewing Bearings: Use cylindrical rollers, tapered rollers, or crossed rollers, offering high load-bearing capacity, particularly suitable for bearing radial forces and overturning moments.

Typical Applications: Tower cranes, tunnel boring machines, steel structure rotary tables.

2. Classification by Structural Form

Single-row slewing bearings: Compact structure, moderate load-bearing capacity, suitable for small and medium-sized machinery.

Double-row slewing bearings: Rolling elements are arranged in two rows, increasing load-bearing capacity, suitable for medium and large-sized machinery.

Four-point contact slewing bearings: A single row of steel balls can withstand both positive and negative axial loads and radial forces, widely used in engineering machinery.

3. Classification by Installation Method

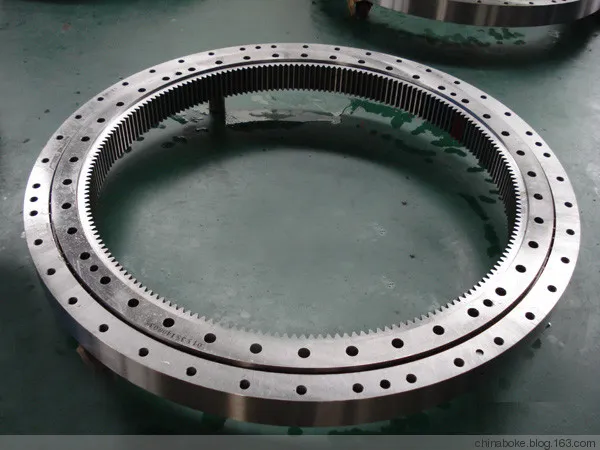

Internal gear slewing bearings: Gear ring is on the inner ring, commonly used in turntables, rotary worktables, etc.

External gear slewing bearings: Gear ring is on the outer ring, suitable for gear-driven equipment.

Gearless slewing bearings: Rotation is achieved through hydraulic or direct drive, mostly used in high-precision machinery.

Slewing Bearing Selection Guide

Choosing the right slewing bearing not only ensures stable equipment operation but also reduces maintenance costs and extends service life. The following factors should be considered when selecting slewing bearings:

Load Type and Size

Small, light-load equipment can use ball bearings.

Medium-to-large equipment with high load-bearing requirements should use roller bearings or crossed roller bearings.

…

For more detailed information on slewing bearing classifications, please click to visit: https://www.mcslewingbearings.com/a/news/slewing-bearing-classification.html