Aluminum Coil Installation and Maintenance: Practical Guide for Optimal Performance

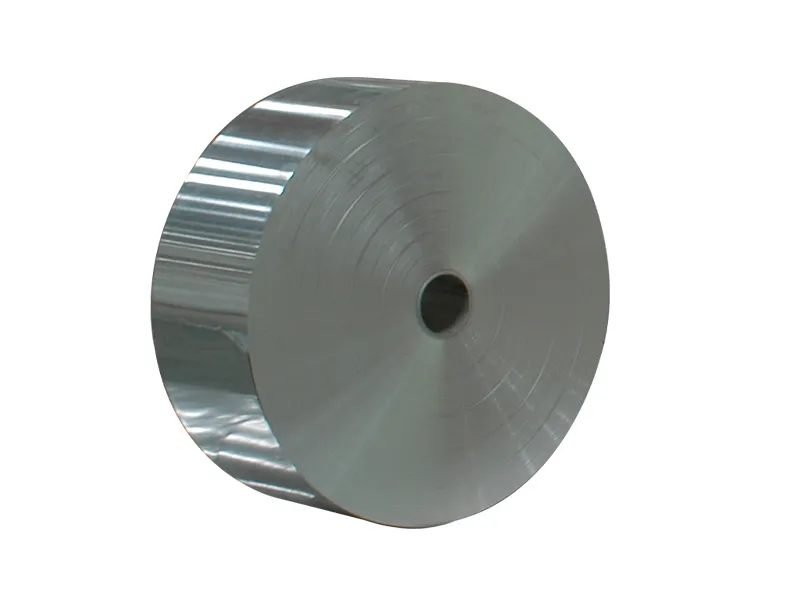

Aluminum coils are critical components across industries such as construction, automotive, HVAC, and packaging. Ensuring their proper installation and routine maintenance is key to maximizing durability, safety, and performance. This guide provides actionable tips to help you manage aluminum coils effectively, prevent damage, and extend service life.

Aluminum Coil Installation and Maintenance Tips

1. Proper Storage Before Installation

Before installing aluminum coils, store them in a dry, well-ventilated area away from direct sunlight, moisture, or corrosive environments. High humidity or water exposure can cause oxidation or surface corrosion, affecting both appearance and functionality. Always place coils on pallets or racks to prevent direct floor contact and minimize the risk of trapped moisture.

2. Safe Handling Techniques

Aluminum coils are heavy and can be easily damaged if mishandled. Use lifting equipment such as cranes or forklifts equipped with soft slings to avoid scratches, dents, or deformation. Never drag coils across rough surfaces, and ensure edges are protected during transport and installation. Proper handling maintains both the aesthetic quality and structural integrity of the material.

3. Installation Best Practices

Surface Preparation: Clean the installation area thoroughly to remove dust, grease, or debris.

Correct Alignment: Align coils carefully to prevent stress points that could cause warping or misfits.

Fastening: Use manufacturer-recommended fasteners, and avoid over-tightening which may deform the coil.

Expansion Allowance: Aluminum expands and contracts with temperature changes; leave sufficient spacing to accommodate thermal expansion.

…

For more detailed information on aluminum coil installation and maintenance, please click to visit:https://www.dw-al.com/a/news/aluminum-coil-installation-and-maintenance-tips.html