How to customize a wind tower welding production line

Customizing a┬Āwind tower welding production line┬Āinvolves a comprehensive assessment of your specific manufacturing needs and then selecting and integrating the appropriate automated machinery to meet those requirements. This process is highly specialized and requires a tailored approach rather than a one-size-fits-all solution.

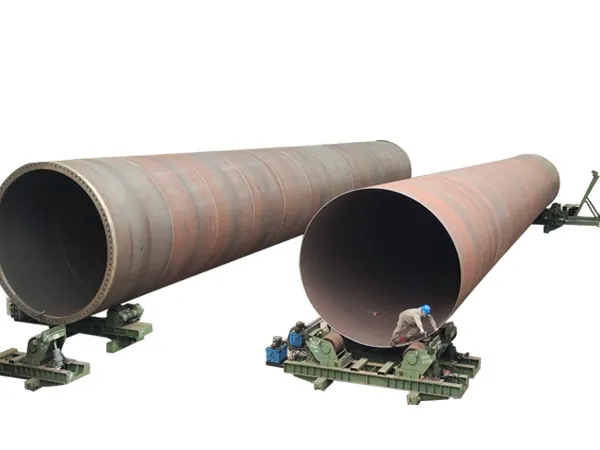

Customized Wind Tower Welding Production Line

1. Key Factors for Customization

To effectively customize a production line, you must first define your operational goals and constraints. These factors will dictate the design and equipment of your line.

Production Capacity: Determine the number of tower sections or entire towers you need to produce per week, month, or year. This directly influences the required welding speed, material handling capacity, and the overall level of automation.

Tower Specifications: The dimensions and materials of the towers you will produce are critical.

Diameter and Thickness: The range of diameters and steel plate thicknesses you plan to use will determine the size and power of key equipment like plate rolling machines and welding power sources.

Section Length: The standard length of your tower “cans” dictates the required length of welding manipulators and the overall workshop layout.

Material Grade: Different steel grades have unique welding requirements that will influence the choice of welding processes and consumables.

Workshop Layout: The physical space of your facility is a major constraint.

Available Space: Map out your facility to account for the entire production flow, from raw material storage to finished product handling.

Ceiling Height and Crane Capacity: Ensure your overhead cranes can handle the largest and heaviest tower sections.

Material Flow: Design a logical, linear flow to minimize unnecessary handling and movement.

2. Key Customization Areas

Material Handling Systems:

Automated Loading/Unloading: Implement robotic or gantry systems for efficient movement of tower sections.

Conveyors and Rollers: Customize the size and type of conveyors to handle the dimensions and weight of your specific tower sections.

Positioners and Rotators: Utilize heavy-duty positioners and rotators to allow for optimal welding angles and access.

Fit-Up Stations: Design specialized fit-up stations that ensure precise alignment of tower sections before welding.

Welding Process Optimization:

Welding Method Selection: Choose the most suitable welding processes for wind tower fabrication (e.g., submerged arc welding (SAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW)).

Automated Welding Carriages: Integrate automated welding carriages that can traverse the tower sections, maintaining consistent speed and arc length.

Multi-Wire Welding: Consider multi-wire SAW systems for increased deposition rates and faster welding.

Narrow Gap Welding: Implement narrow gap welding techniques to reduce weld volume and improve efficiency.

Robotic Welding Cells: For specific, repetitive tasks or complex geometries, robotic welding can offer high precision and repeatability.

Quality Control and Inspection:

Non-Destructive Testing (NDT): Integrate automated NDT systems (e.g., ultrasonic testing, eddy current testing) directly into the production line to ensure weld integrity.

Vision Systems: Implement vision systems for real-time weld monitoring, defect detection, and precise seam tracking.

Data Logging and Traceability: Establish systems to record welding parameters and inspection results for comprehensive traceability.

Automation and Control Systems:

PLC/HMI Control: Implement a centralized PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for comprehensive control and monitoring of the entire line.

…

For more detailed information on how to customize the wind turbine tower welding production line, please click here:┬Āhttps://www.bota-weld.com/en/a/news/customized-wind-tower-welding-production-line.html