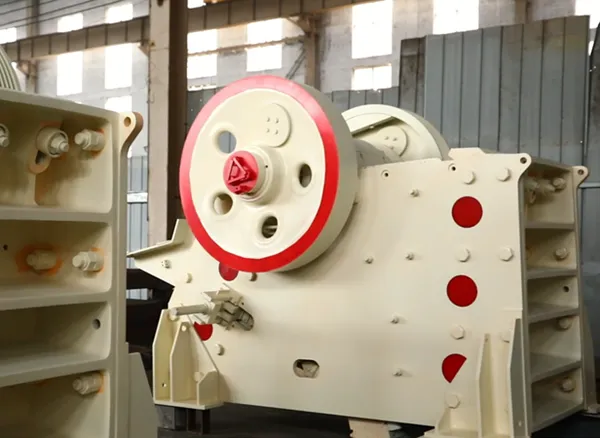

Jaw Crusher Troubleshooting Guide: Common Issues & Fixes

Jaw crushers are robust machines essential for primary crushing in various industries, but like any heavy equipment, they can experience issues. Regular maintenance and prompt troubleshooting are key to minimizing downtime and ensuring efficient operation.

Common Jaw Crusher Issues and Their Solutions

1. Main Engine Suddenly Stops or Fails to Start

Possible Causes:

Crushing chamber/discharge port blockage: Material buildup can halt the machine.

V-belt issues: Loose, broken, or slipping V-belts.

Eccentric shaft bushing problems: Loose bushing can cause the eccentric shaft to get stuck.

Low voltage/insufficient motor power: Electrical issues can prevent the motor from driving the sheave.

Damaged bearings: Worn or damaged bearings can cause the machine to seize.

Fixes:

Clear blockages: Stop the crusher and remove any material blocking the discharge port or crushing chamber.

Check and adjust V-belts: Tighten loose V-belts or replace broken ones.

Reinstall/replace bushing: If the eccentric shaft bushing is loose, reinstall or replace it.

Adjust voltage: Ensure the working voltage meets the motor’s requirements.

Replace bearings: If bearings are damaged, replace them.

2. Reduced Crushing Capacity / Output Does Not Meet Standards

Possible Causes:

Incorrect feed size: Material fed into the crusher is too large, causing clogging.

Worn jaw plates: Worn or unevenly worn jaw plates reduce crushing efficiency.

Improper settings: Incorrect eccentric speed, stroke length, or discharge opening settings.

Clogged discharge chute: Material buildup in the discharge chute can cause back-pressure.

Incorrect relative position of jaw plates: The tooth grooves of the movable and fixed jaw plates are misaligned.

Voltage too low: Insufficient power to the motor.

…

More detailed information about Jaw Crusher Troubleshooting Guide can be found by clicking Visit: https://www.yd-crusher.com/a/news/jaw-crusher-troubleshooting-guide.html